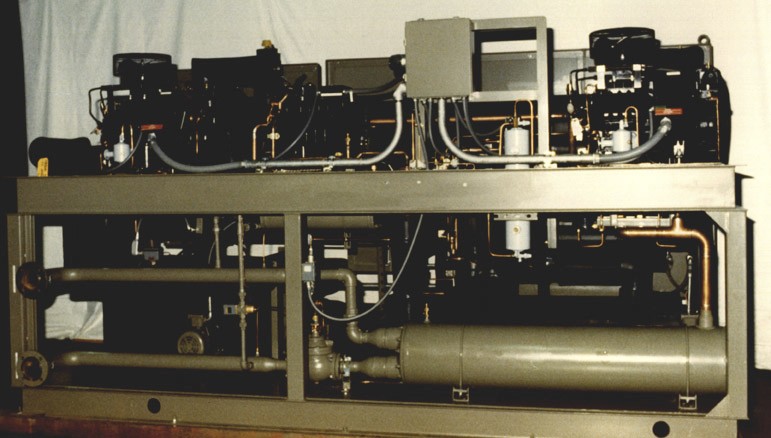

Rowald Refrigeration Systems Photo Catalog

Model: WBI-5700/3-2R3P-EG

Nominal Horsepower: 57

Condenser: Water-cooled

Evaporator: Two, Direct Expansion

Coolant: 50% Ethylene Glycol

Coolant Temperature Circuit #1: -22°F

Coolant Temperature Circuit #2: 10°F

Capacity Circuit #1: 47,700 Btu/h @ -42° SST, 105°F SDT, and 85°F Cooling Water

Capacity Circuit #2: 97,600 Btu/h @ -5° SST, 105°F SDT, and 85°F Cooling Water

Application: Thermal Shock

Customer: FORD MOTOR COMPANY

SYSTEM OVERVIEW

The THERMAL SHOCK SYSTEM is designed to allow the thermal cycling of one automotive engine in one test room. The design allows for room be able to perform up to three thermal cycles per hour. One temperature thermal shock is provided for, at -20°F. The cycles operate as follows:

THERMAL SHOCK

An engine is run for fifteen minutes on the "tower" cooling system. The coolant is warmed to the operating condition. At the end of the fifteen-minute period, the engine is stopped. The room's shock valves switch positions and coolant flow is transferred from the "tower" to the -20°F COLD TANK. The cold coolant chills the engine to -20°F and maintains it at this temperature for a fifteen-minute period while the engine is stopped. At the end of this fifteen-minute period the shock valves return to the "tower" flow position, the engine is restarted and the cycle begins again.

EQUIPMENT

A VALVE RACK controls the glycol flow and direction for the test room. The rack is mounted on the hot and cold tank skid (not shown). The valve rack direct the flow of glycol to and from the engine, cold tank and hot tank. These valves, however, do not control the shock sequence of the engines. The valves that perform the shocks are controlled by the test room's PLC. The shock control valves are located after the valve racks.

A HOT TANK is located on the tank skid. These tanks collect the hot glycol from the engine when a -20°F shock is performed. A pump circulates glycol from the hot tank to the 10°F evaporator and back to the hot tank.

A COLD TANK holds -22°F glycol for use by the room for cold shocks. The cold tank will be full when the hot tank is at its minimum level. The cold tank is cooled by its own evaporator. A recirculating pump moves the glycol from the cold tank through the evaporator and back to the cold tank. A main supply pump provides -22°F glycol to the valve racks for the cold shocks.